In the second half of the twentieth century, some of the best rechargeable chemical current sources were rechargeable batteries made using nickel-cadmium technology. They are still widely used in various fields due to their reliability and unpretentiousness.

Content

- What is Nickel Cadmium Battery

- The principle of operation and the device Ni-Cd battery

- Specifications and what are Ni-Cd batteries

- Where are nickel-cadmium batteries used?

- Pros and Cons of Ni-Cd Battery

- Difference of Ni-Cd from Li-Ion or Ni-Mh sources

- Terms of Use

- How to Recover Ni Cd Battery

- Storage and disposal

What is Nickel Cadmium Battery

Nickel-cadmium batteries are galvanic rechargeable current sources, which were invented in 1899 in Sweden by Waldmar Jungner. Until 1932, their practical use was very limited due to the high cost of the metals used in comparison with lead-acid batteries.

Improving the technology of their production led to a significant improvement in their operational characteristics and allowed in 1947 to create a sealed maintenance-free battery with excellent parameters.

The principle of operation and the device Ni-Cd battery

These batteries produce electrical energy due to the reversible interaction of cadmium (Cd) with nickel oxide-hydroxide (NiOOH) and water, resulting in the formation of nickel hydroxide Ni (OH) 2 and cadmium hydroxide Cd (OH) 2, which causes the appearance of an electromotive force.

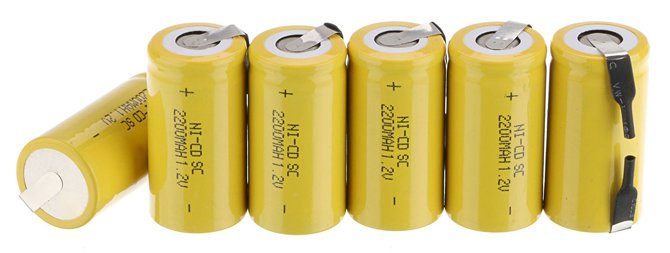

Ni-Cd batteries are produced in sealed enclosures that contain electrodes separated by a neutral separator, containing nickel and cadmium, which are in a solution of a jelly-like alkaline electrolyte (usually potassium hydroxide, KOH).

The positive electrode is a steel mesh or foil coated with a nickel oxide-hydroxide paste mixed with a conductive material

The negative electrode is a steel mesh (foil) with pressed porous cadmium.

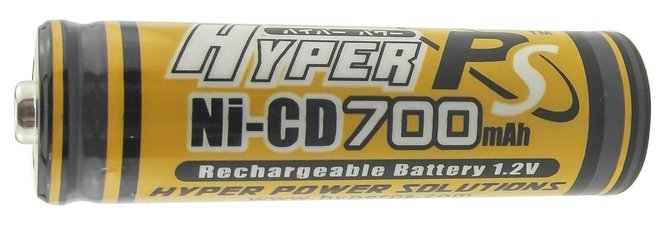

One nickel-cadmium element is capable of delivering a voltage of about 1.2 volts, therefore, to increase the voltage and power of the batteries in their design, many parallel electrodes are used, separated by separators.

Specifications and what are Ni-Cd batteries

Ni-Cd batteries have the following specifications:

- the discharge voltage of one element is about 0.9-1 volts;

- the nominal voltage of the element is 1.2 v, to obtain voltages of 12v and 24v, a series connection of several elements is used;

- voltage of a full charge - 1.5-1.8 volts;

- working temperature: from -50 to +40 degrees;

- number of charge-discharge cycles: from 100 to 1000 (in the most modern batteries - up to 2000), depending on the technology used;

- self-discharge level: from 8 to 30% in the first month after a full charge;

- specific energy consumption - up to 65 W * hour / kilogram;

- service life - about 10 years.

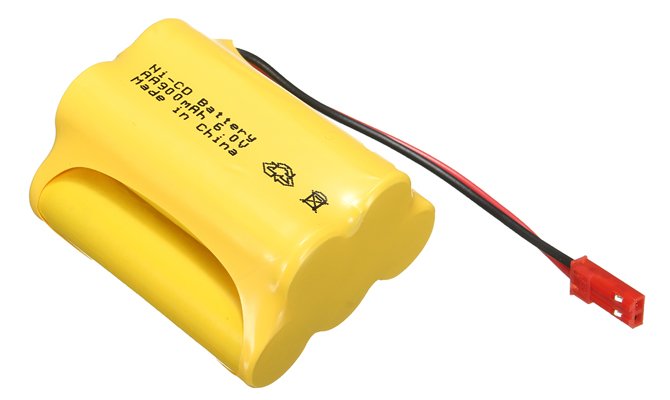

Ni-Cd batteries are produced in various cases of standard sizes and in non-standard design, including disk, hermetic form.

Where are nickel-cadmium batteries used?

These batteries are used in devices that consume high currents, and also experience high loads during operation in the following cases:

- on trolleybuses and trams;

- on electric cars;

- on sea and river transport;

- in helicopters and airplanes;

- in power tools (screwdrivers, drills, electric screwdrivers and others);

- electric shavers;

- in military equipment;

- portable radio stations;

- in toys on the radio;

- in the lights for diving.

Currently, due to the tightening of environmental requirements, most batteries of popular sizes (AA, AAA and others) is produced by nickel-metal hydride and lithium-ion technologies. However, many Ni Cd batteries of various sizes, released several years ago, are still in operation.

Ni-Cd cells have a long service life, which sometimes exceeds 10 years, and therefore this type of battery can still be found in a variety of electronic devices, except for those listed above.

Pros and Cons of Ni-Cd Battery

This type of battery has the following positive characteristics:

- long life and the number of charge-discharge cycles;

- long service life and storage;

- the ability to quickly charge;

- ability to withstand heavy loads and low temperatures;

- maintaining operability in the most adverse operating conditions;

- low cost;

- the ability to store these batteries in discharged condition for up to 5 years;

- medium overcharge resistance.

At the same time, nickel-cadmium power supplies have several disadvantages:

- the presence of a memory effect, manifested in the loss of capacity when charging the battery, without waiting for a full discharge;

- the need for preventive work (several charge-discharge cycles) to achieve full capacity;

- full restoration of the battery after long-term storage requires three to four cycles of full charge-discharge;

- large self-discharge (about 10% in the first month of storage), leading to almost full battery discharge during the year of storage;

- low energy density compared to other batteries;

- the high toxicity of cadmium, due to which they are banned in a number of countries, including the EU, the need to dispose of such batteries on special equipment;

- more weight than modern batteries.

Difference of Ni-Cd from Li-Ion or Ni-Mh sources

Batteries with active components, including nickel and cadmium, have a number of differences from more modern lithium-ion and nickel-metal hydride sources of electricity:

- Ni-Cd elements, unlike Li-ion and Ni-mh options have a memory effect, have a lower specific capacity at the same size;

- NiCd sources are more unpretentious, maintain performance at very low temperatures, are many times more resistant to overcharge and strong discharge;

- Li-Ion and Ni-Mh batteries are more expensive, afraid of overcharging and strong discharge, but have less self-discharge;

- the life and storage of Li-Ion batteries (2-3 years) is several times shorter than Ni Cd products (8-10 years);

- nickel-cadmium sources quickly lose capacity when used in a buffer mode (for example, in UPS). Although they can then be completely restored by deep discharge and charge, it is better not to use Ni Cd products in devices where they are constantly recharged;

- the same charge mode of Ni-Cd and Ni-Mh batteries allows you to use the same chargers, but you must take into account the fact that nickel-cadmium batteries have a more pronounced memory effect.

Based on the differences, it is impossible to draw an unambiguous conclusion about which batteries are better, since all elements have strengths and weaknesses.

Terms of Use

During operation in Ni Cd power sources, a number of changes occur that lead to a gradual deterioration in performance and, ultimately, to loss of performance:

- effective area and mass of electrodes decreases;

- the composition and volume of the electrolyte changes;

- decomposition of the separator and organic impurities;

- water and oxygen are lost;

- Current leaks occur due to the growth of cadmium dendrites on the plates.

In order to minimize damage to the battery that occurs during its operation and storage, it is necessary to avoid adverse effects on the battery, which are associated with the following factors:

- the charge of an incompletely charged battery leads to a reversible loss of its capacity due to a decrease in the total area of the active substance as a result of crystal formation;

- regular strong recharge, which leads to overheating, increased gas formation, loss of water in the electrolyte and destroys the electrodes (especially the anode) and the separator;

- undercharging, leading to premature depletion of the battery;

- long-term operation at very low temperatures leads to a change in the composition and volume of the electrolyte, the internal resistance of the battery increases and its performance deteriorates, in particular, the capacity decreases.

With a strong increase in pressure inside the battery as a result of a fast charge with a large current and strong degradation of the cadmium cathode, excess hydrogen can be released into the battery, which leads to a sharp increase in pressure, which can deform the case, violates the assembly density, increases internal resistance and reduces the operating voltage.

In batteries equipped with an emergency pressure relief valve, the risk of deformation can be prevented, but irreversible changes in the chemical composition of the battery cannot be avoided.

Charging Ni Cd batteries must be carried out with a current of 10% (if necessary, a quick charge in special batteries with a current of up to 100% per 1 hour) of their capacity (for example, 100 mA at a capacity of 1000 mAh) for 14-16 hours. The best mode of their discharge is a current equal to 20% of the battery capacity.

How to Recover Ni Cd Battery

In case of loss of capacity, nickel-cadmium power supplies can be almost completely restored using a full discharge (up to 1 volt per cell) and subsequent charge in standard mode. This training of batteries can be repeated several times for the most complete restoration of their capacity.

If it is not possible to restore the battery by discharge and charge, you can try to restore them by applying short current pulses (tens of times larger than the capacity of the restored element) for several seconds. This effect eliminates the internal circuit in the battery cells that occurs due to the growth of dendrites by burning them with a strong current. There are special industrial activators that carry out this effect.

Full restoration of the initial capacity of such batteries is impossible due to irreversible changes in the composition and properties of the electrolyte, as well as degradation of the plates, but makes it possible to extend the life of the battery.

The method of recovery at home is to carry out the following actions:

- a wire with a cross section of at least 1.5 square millimeters is connected minus the restored cell with the cathode of a powerful battery, such as a car or UPS;

- the second wire is securely attached to the anode (plus) of one of the batteries;

- for 3-4 seconds, the free end of the second wire quickly touches the free plus terminal (with a frequency of 2-3 touches per second). In this case, it is necessary to prevent welding of wires at the junction;

- with a voltmeter, the voltage at the source being restored is checked; in its absence, another recovery cycle is done ;;

- when an electromotive force appears on the battery, it is put on charge;

In addition, you can try to destroy the dendrites in the battery by freezing them for 2-3 hours, followed by their sharp tapping. When frozen, dendrites become brittle and are destroyed by shock, which theoretically can help get rid of them.

There are more extreme recovery methods associated with the addition of distilled water to old elements by drilling their bodies. But the full provision of the tightness of such elements in the future is very problematic. Therefore, you should not save and expose your health to the risk of poisoning with cadmium compounds due to the gain of several work cycles.

Storage and disposal

It is better to store nickel-cadmium batteries in a discharged state at a low temperature in a dry place. The lower the storage temperature of such batteries, the less self-discharge they have. High-quality models can be stored for up to 5 years without significant damage to the technical characteristics. To put them into operation, it is enough to charge them.

Harmful substances contained in one AA battery can contaminate about 20 square meters of territory. For the safe disposal of Ni Cd batteries, they must be taken to recycling points, from where they are sent to factories, where they must be destroyed in special sealed furnaces equipped with filters that capture toxic substances.