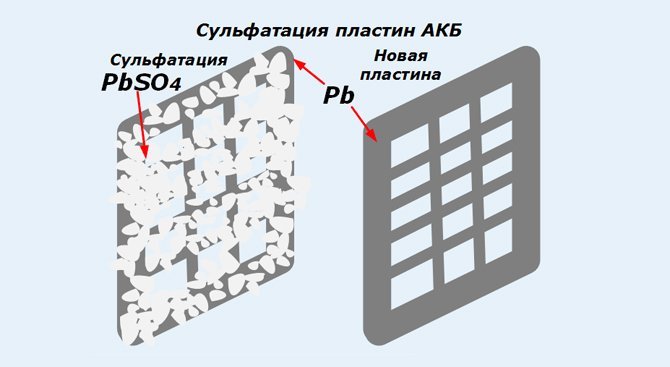

The battery life directly depends on the amount of lead sulfate deposits on the surface of the plates. Sulphation is an inevitable process during battery operation, but this phenomenon can not only be fought, but also significantly reduced the thickness of this dielectric.

Content

What is battery desulfation and what is it done for

Desulphation is called work aimed at cleaning the battery plates from lead sulfate. After cleaning the plates, the battery capacity will be significantly increased.

Restoring the conductivity of the plates will allow you to confidently start the car at any ambient temperature, and the battery life will increase significantly. You can destroy the film of lead sulfate on your own at home.

Battery Desulfation Methods

There are a large number of different methods for restoring battery capacity, but most often electric current or chemicals are used for this purpose. A simple option to clean the plates from the sulfate film is to use a charging electric current. To carry out the work, you will need to purchase or make a device yourself, which allows you to adjust the voltage and current strength.

For the chemical method, you do not need to use any devices or mechanisms, but to perform cleaning in this way, you will need to perform more operations.

Using a charger

Using a charger, you can clean the plates of lead sulfate in two ways:

- A charger is connected to the battery. The charge current should be 0.04% of the nominal battery capacity. The voltage is set to 14 V when charging a conventional battery and to 16 V when restoring a calcium battery. The duration of the procedure should be about 8 hours, after which it is necessary to pause 12 to 14 hours. After the break, you should repeat the charging cycle with the same current and voltage indicators. Thus, for effective cleaning of lead plates, it will be necessary to carry out 4 to 5 complete cycles.

- The second option to restore the capacity can only be done on a serviced battery. To conduct the process of cleaning plates from lead sulfate, you must:

- Charge the battery with a current equal to 10% of its capacity.

- Drain the electrolyte.

- Pour in distilled water.

- Charge the battery for 10 days. During charging, you should experimentally establish the voltage at which the process of gas formation is practically not formed.

- After 10 days, the electrolyte is drained and refilled with clean distilled water.

- The battery charges again within 10 days.

- At the end of the cycle, the water drains and the battery is filled with new electrolyte.

After filling the electrolyte, the battery is again charged with a current of 10% of capacity and a voltage of 14 V. This mode of battery recovery will be especially effective if the battery charging cycles with clean water are repeated until after a 10-day period its density is reached increase.

DIY battery desulfation

An equally effective method of purification from lead sulfate is washing cans with chemically active substances.As you know, acidic compounds react with alkali, therefore, to carry out desulfation with your own hands using chemistry, you will need to purchase a suitable reagent.

With the task of splitting sulfate plaque, baking soda will help. For the procedure, it is necessary:

- Drain electrolyte from battery.

- Dissolve alkali in distilled water in a ratio of 1 to 3.

- Heat the mixture to a boil.

- Pour hot alkaline solution into battery banks for 30 to 40 minutes.

- Drain the alkaline solution.

- Rinse the battery at least 3 times with clean hot water.

- Pour electrolyte into jars.

If the procedure of chemical desulfation of the plates was carried out carefully, then the battery capacity will increase significantly. It can be used for a long time until plaque again forms on the plates.

How to choose a device with desulfation

Despite the fact that the process of desulfation can be carried out using a simple charger, greater efficiency, with less time, can be achieved if you use special memory. The most high-quality chargers equipped with a desulfation function are:

- Pennant 55 is a relatively inexpensive charger equipped with built-in programs for charging various batteries, as well as the function of desulfation of battery plates.

- “Polyus-912T” - the device is also equipped with a cyclic program, which will make it easy to restore old, oxide-coated batteries. The device is ideal for desulfation of maintenance-free batteries, because the entire process of plate recovery is carried out automatically.

- OptiMate PRO 8 is a professional charging station with battery recovery function. Allows you to simultaneously charge up to 8 batteries with a voltage of 6 or 12 volts. The device can be effectively used to charge not only automobile batteries, but also to restore the charge of stationary high-power devices operating in uninterruptible power systems.

In addition to using factory models of chargers equipped with a desulfation function, it is possible to make a self-made charger from a transformer, a turn signal relay and a powerful 12-volt light bulb. Such a blinker for desulfation will be no less effective, and the cost of manufacture will be minimal.

How to reduce sulfation?

As you know, the disease is easier to prevent than subsequently deal with its treatment. The process of coating the plates with lead sulfate is natural, but under certain conditions, the intensity of sulfation can increase many times. To prevent such situations during battery operation, it is necessary:

- Only store the battery in a charged state.

- In the summer, on serviced batteries, a periodic check of the electrolyte level should be carried out.

- Avoid deep discharges during operation.

The implementation of these simple rules will allow you to last a lead battery for at least 5 years, while its main performance indicators will decrease gradually.

Still have questions aboutDesulfation or have something to add? Then write to us about it in the comments, this will make the material more useful, complete and accurate.